Scientists from KU Leuven have discovered how oil penetrates snacks during and after the frying process. Recent research findings point to advanced frying techniques that reduce oil absorption, as well as innovative methods to limit oil uptake during the cooling phase. This paves the way for the development of healthier snacks without compromising on taste and texture.

“Frying is a popular food preparation method, especially in Western diets”, explains researcher Pieter Verboven of KU Leuven MeBioS. “It’s quick, tastes good and produces a crispy coating with a soft interior. The downside, however, is that the process often results in a high fat content in food and it frequently involves ultra-processed products that should be consumed in moderation.” The current nutritional guidelines from the World Health Organisation (WHO) recommend limiting total fat intake to 30% of overall energy intake. The relevance of health issues has increased and the research was supported by the Research Foundation – Flanders.

Until recently, it was a challenge to understand in detail what happens inside our food during the frying process, specifically how and when oil penetrates fried products.

Pressure-driven phenomenon

Earlier studies viewed oil absorption mainly as a surface phenomenon, focusing on surface properties such as surface roughness and oil permeability as determining factors for the adhesion of frying oil to the exterior of fried products. Today, oil uptake is widely recognised as a pressure-driven process. The positive internal pressure, created during water evaporation and product expansion, inhibits oil penetration during frying. During cooling, however, the condensation of the steam causes the surface oil to be drawn into your food’s internal matrix. This is due to the favourable pressure gradient that develops at that stage.

“The frying process in the frying pan happens extremely quickly. Within seconds, the water inside the food evaporates and is expelled as steam. The product expands, forming a porous structure, but capturing this process in detail was a huge challenge”, says Verboven.

4D imaging system

To achieve this, the researchers made use of 4D imaging technology (three spatial dimensions plus time) at the European Synchrotron Radiation Facility (ESRF) in Grenoble, France. The technology generates X-rays that are 100 billion times more intense than those used in medical settings.

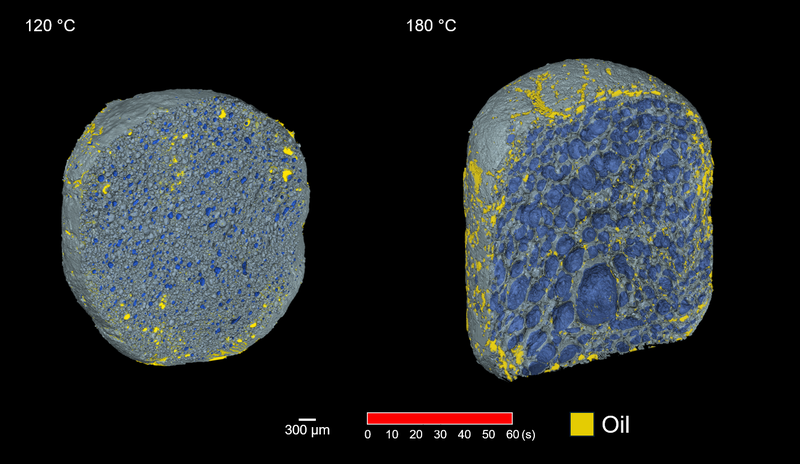

“At higher temperatures (180°C), the fried product develops a hard crust with small pores that draw in oil through capillary action after frying”, explains researcher Isabella Maria Riley from the Laboratory of Food Chemistry and Biochemistry, part of the Department of Microbial and Molecular Systems.

At lower temperatures (120°C), the structure remains softer and oil absorption is more limited. A remarkable finding is that the majority of the oil is not absorbed during frying but immediately afterwards. When food is removed from hot oil and begins to cool, the pressure difference between the interior and exterior draws oil into the product. The oil is primarily absorbed through the small pores in the crust. This confirms that the cooling phase is a critical stage during which oil uptake can be reduced through strategic process modifications.

“Controlling pore formation and adjusting cooling strategies makes it possible to develop healthier snacks without compromising on taste or texture”, concludes Pieter Verboven.

Oil uptake shown in yellow, 60 seconds after frying. Left: fried at 120°C, right: at 180°C. Source: KU Leuven

Publication

High-speed computed tomography to visualise the 3D microstructural dynamics of oil uptake in deep-fried foods door Verma, U., Riley, I.M., Lukić, B. et al., Nature Communications, 2025

“It is always advisable to maintain a critical perspective on your own products and adjust them to contemporary needs where necessary”, emphasises Marijke Adriaens, CEO of frozen food company Fribona. “For consumers, taste is still the main consideration. It is essential to work towards a product that is, above all, tasty and visually appealing.”...

Food companies are increasingly targeting a wider range of consumer groups. Speaking at an event organised by Fenavian, Julian Mellentin of New Nutrition Business said this strategy offers significant opportunities to respond to the diverse health needs and interests of today’s consumers. “Consumers enjoy both animal and plant-based proteins”, he...

Backed by financial partners, Start it @KBC is launching the accelerator programme Scale it Agro, aimed at scale-ups offering sustainable and innovative agricultural solutions for agriculture and horticulture businesses. Kjell Clarysse, programme director at Scale it Agro, goes into more detail.

With the right processing, Chlorella vulgaris can serve as a promising and sustainable protein source capable of replacing both plant-based and animal-derived proteins. While challenges remain around taste and the efficiency of protein extraction, microalgal proteins could serve as a supplement to sustainable and innovative food products. These...